Ingxubevange 600 Stainless Steel Coil Tubing Price

Ukuqulunqwa kwemichiza, %

Ukusetyenziswa kwe-corrosion eqhelekileyo kubandakanya ukuveliswa kwe-titanium dioxide (umzila we-chloride), i-perchlorethylene syntheses, i-vinyl chloride monomer (VCM), kunye ne-magnesium chloride.I-alloy 600 isetyenziselwa ukuveliswa kweekhemikhali kunye nokutya kunye nokugcinwa, ukunyanga ukushisa, i-phenol condensers, ukuveliswa kwesepha, imifuno kunye nemifuno ye-asidi enamafutha kunye nezinye ezininzi.

| I-Ni + Co | Cr | Fe | C | Mn | S | Si | Cu |

| 72.0 imiz | 14.0-17.0 | 6.0-10.0 | .15 ubuninzi | 1.00 ubuninzi | .015 ubuninzi | .50 ubuninzi | .50 ubuninzi |

Zeziphi izicelo ezisetyenziswa kwi-Inconel 600?

- Ishishini lemichiza

- I-Aerospace

- Ishishini lokunyanga ubushushu

- Imveliso yePulp kunye nephepha

- Ukulungiswa kokutya

- Ubunjineli beNyukliya

- Amacandelo einjini yegesi

Iimpawu zeASTM

| Umbhobho Smls | Umbhobho Welded | Umbhobho Smls | Umbhobho Welded | Icwecwe/ipleyiti | Ibha | Ukuqulunqa | Ukulinganisa | Ucingo |

| B167 | B517 | B163 | B516 | B168 | B166 | B564 | B366 |

Iipropati zoomatshini

Iqondo lobushushu legumbi eliqhelekileyo Iipropati ze-Tensile ye-Annealed Material

| Ifom yeMveliso | Imeko | I-Tensile (ksi) | .2% isivuno (ksi) | Ubude (%) | Ukuqina (HRB) |

| Rod & Bar | Ukutsalwa ngokubanda | 80-100 | 25-50 | 35-55 | 65-85 |

| Rod & Bar | Ishushu-Igqityiwe | 80-100 | 30-50 | 35-55 | 65-85 |

| Umbhobho kunye noMbhobho | Ishushu-Igqityiwe | 75-100 | 25-50 | 35*55 | - |

| Umbhobho kunye noMbhobho | Ukutsalwa ngokubanda | 80-100 | 25-50 | 35-55 | 88 ubuninzi |

| Ipleyiti | I-Hot-Rolled | 80-105 | 30-50 | 35-55 | 65-85 |

| Iphepha | Ukutsalwa ngokubanda | 80-100 | 30-45 | 35-55 | 88 ubuninzi |

Inconel 600 Melting Point

| Isiqalelo | Ukuxinana | Indawo yokunyibilika | Tensile strength | Ukomelela kweSivuno (0.2% i-offset) | Elongation |

| Ingxubevange 600 | 8.47 g/cm3 | 1413 °C (2580 °F) | Psi – 95,000 , MPa – 655 | Psi – 45,000 , MPa – 310 | 40% |

Inconel 600 Equivalent

| UMGANGATHO | WERKSTOFF NR. | UNS | I-JIS | BS | IGOST | I-FNOR | EN |

| Ingxubevange 600 | 2.4816 | N06600 | NCF 600 | NA13 | МНЖМц 28-2,5-1,5 | NC15FE11M | I-NiCr15Fe |

Ingxubevange 600 Tubing

I-alloy 600 ingumgqatswa ogqwesileyo wosetyenziso oluninzi kumaqondo obushushu aphezulu kakhulu kunye neemeko ezingqongileyo ezinokonakala.Umxube we-nickel kunye ne-chromium uvelisa ukuxhathisa okuqinileyo kwi-oxidation kumaqondo obushushu okusebenza.La maqondo obushushu anokusuka kwi-cryogenic ukuya kumanqanaba atshisayo angama-2,000°F.Umxholo ophezulu we-nickel we-alloy 400 unika kwakhona ukuchasana okuphantse kuphele ukunyanzeliswa kwe-corrosion cracking, efumaneka ngokuqhelekileyo kwiindawo ze-chloride.

Kubalulekile ukuqaphela ukuba inxalenye yechromium yeprofayili yekhemikhali yealloyi yenza ukuba ibakala likwazi ukumelana namaqondo obushushu aphezulu.Ulwakhiwo olucolekileyo lweenkozo lombhobho ogqityiweyo obandayo, ukongezelela, luzisa ukuxhathisa okungcono kokubola, okubandakanya ukudinwa okuphezulu kunye nefuthe lamandla amandla.

IiNkcazo zeMveliso

ASTM B163, B167 / ASME SB163 / NACE MR0175, MR0103

Ubungakanani Uluhlu

| Idayamitha yangaphandle (OD) | Ukutyeba kweendonga |

| .250”–.750” | .035”–.083” |

IiMfuno zeMichiza

Ingxubevange 600 (UNS N06600)

Ukuqamba %

| Ni Nickel | Cu Ubhedu | Fe Intsimbi | Mn IManganese | C Ikhabhoni | Si Isilicon | S Isulfure | Cr Chromium |

| 72.0 imiz | 0.50 ubuninzi | 6.00–10.00 | 1.00 ubuninzi | 0.15 ubuninzi | 0.50 ubuninzi | 0.015 ubuninzi | 14.0–17.0 |

Ukunyamezelwa kweDimensional

| OD | OD Ukunyamezela | Unyamezelo eludongeni |

| ≤ .500” ngaphandle | +.005” | ± 12.5% |

| .500”–.750” ngaphandle | +.005” | ± 12.5% |

Iipropati zoomatshini

| Unikeze Amandla: | 35 ksi imiz |

| Tensile strength: | 80 ksi imiz |

| Ubude (umzuzu 2"): | 30% |

Ukwenziwa

I-alloy 600 inokudityaniswa ngokulula ngenkqubo eqhelekileyo.Ulawulo lwale alloy lugqwesileyo, luhlala phakathi kokusetyenziswa kwe-T303 kunye ne-T304.

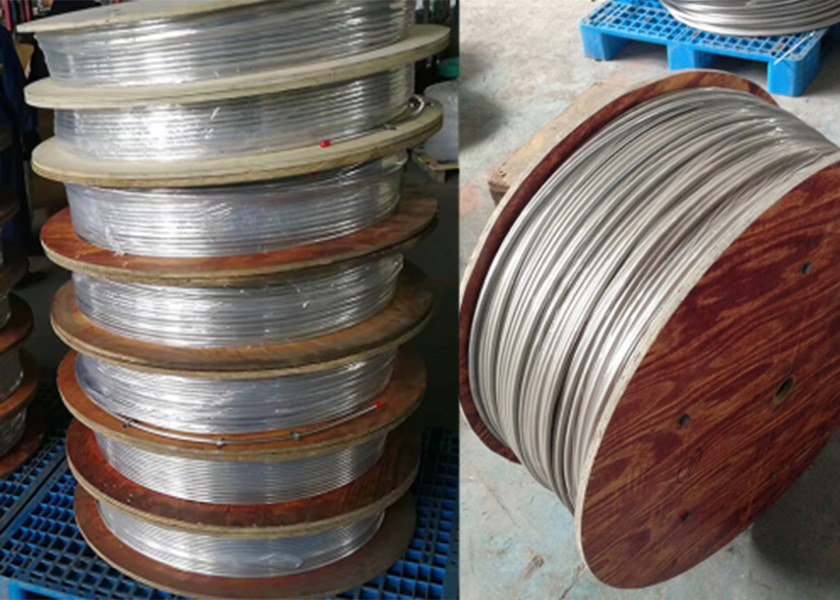

Iifoto zeFactory

Ukuhlolwa

Ukuthumela kunye nokuPakisha

Ingxelo yoVavanyo