Ingxubevange 625 Steel Coil Tubing Price

Ukuqulunqwa kwemichiza, %

I-alloy 625 imathiriyeli ayiyo-magnetic, i-austenitic, kwaye ibonisa amandla aphakamileyo okuxinana, ukwenziwa, kunye nokuqina.Ngenxa yomxholo wayo ophezulu we-nickel, le ngxubevange iphantse yakhuseleka kwi-chloride ion stress-corrosion cracking kunye ne-pitting, edla ngokufunyanwa kwiintsimbi kusetyenziso lwamanzi olwandle olufana nokutshintsha ubushushu, iziqhoboshi, kunye nentambo yokushenxa.

| Cr | Ni | Mo | Co + Nb | Ta | Al | Ti | C |

| 20.00-30.00 | Intsalela | 8.0-10.0 | 1.0 ubuninzi | 3.15-4.15 | .40 ubuninzi | .40 ubuninzi | .10 ubuninzi |

| Fe | Mn | Si | P | S |

| 5.0 ubuninzi | .50 ubuninzi | .50 ubuninzi | .015 ubuninzi | .015 ubuninzi |

Zeziphi izicelo ezisetyenziswa kwi-Inconel 625?

- I-Inconel 625 isetyenziswa kakhulu kwishishini le-Aerospace

- Iinkqubo zokuhambisa iinqwelomoya

- Iinkqubo zokukhupha injini yeJet

- Iinkqubo ze-injini zokutyhalela umva

- Izixhobo ezikhethekileyo zamanzi olwandle

- Izixhobo zenkqubo yeekhemikhali

Iimpawu zeASTM

| Umbhobho Smls | Umbhobho Welded | Umbhobho Smls | Umbhobho Welded | Icwecwe/ipleyiti | Ibha | Ukuqulunqa | Ukulinganisa | Ucingo |

| B444 | B705 | B444 | B704 | B443 | B446 | - | - | - |

Iipropati zoomatshini

| Temp° F | Ukuqina (psi) | .2% isivuno (psi) | Ukwandiswa kwi-2 “ (%) |

| 70 | 144,000 | 84,000 | 44 |

| 400 | 134,000 | 66,000 | 45 |

| 600 | 132,000 | 63,000 | 42.5 |

| 800 | 131,500 | 61,000 | 45 |

| 1000 | 130,000 | 60,500 | 48 |

| 1200 | 119,000 | 60,000 | 34 |

| 1400 | 78,000 | 58,500 | 59 |

| 1600 | 40,000 | 39,000 | 117 |

Inconel 625 Indawo yokunyibilika

| Indawo yokunyibilika | 1290 - 1350 °C | 2350 - 2460 °F |

Inconel 625 Equivalent

| UMGANGATHO | WERKSTOFF NR. | UNS | I-JIS | BS | IGOST | I-FNOR | EN |

| Ikhoneli 625 | 2.4856 | N06625 | NCF 625 | NA 21 | ХН75МБТЮ | NC22DNB4MNiCr22Mo9Nb | I-NiCr23Fe |

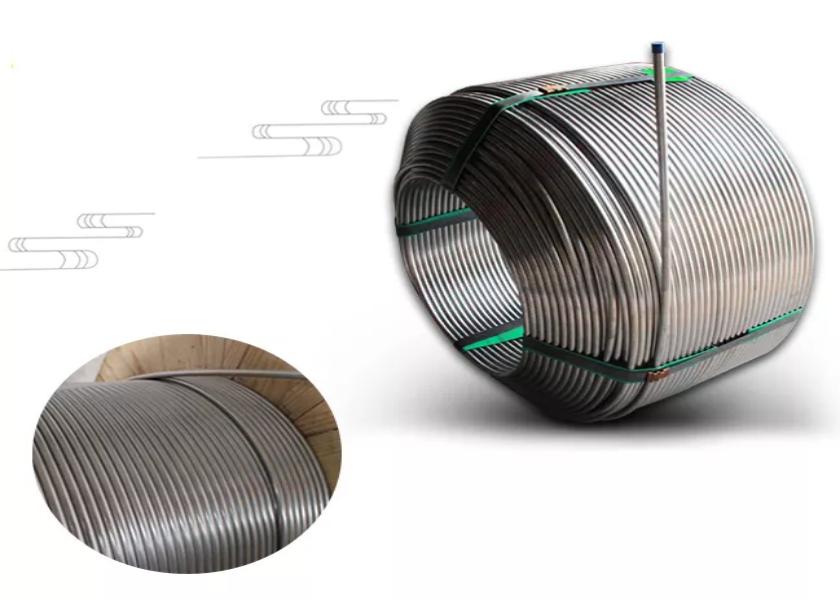

Ingxubevange 625 Tubing

I-alloy 625 yi-austenitic nickel-chromium-molybdenum superalloy eyaziwa ngokuxhathisa kwi-crevice corrosion kunye ne-oxidation kumaqondo obushushu aphezulu.Lamaqondo obushushu anokusuka kwi-cryogenic ukuya kumaqondo ashushu kakhulu angama-1,800°F.Indlela yokuziphatha kunye nokwakheka kweekhemikhali zeli bakala kuyenza ifaneleke kakuhle ukusetyenziswa kwenyukliya kunye ne-aerospace.Kwakhona, ngokudityaniswa kwe-niobium, i-alloy 625 ityhubhu izifumana inamandla anyukileyo ngaphandle kokunyanga ubushushu.Le propati yenza ibakala libe yindlela ebalaseleyo yokwenza.

IiNkcazo zeMveliso

ASTM B444 / ASME SB444 / NACE MR0175

Ubungakanani Uluhlu

| Idayamitha yangaphandle (OD) | Ukutyeba kweendonga |

| .375"-.750" | .035”–.095” |

IiMfuno zeMichiza

Ingxubevange 625 (UNS N06625)

Ukuqamba %

| C Ikhabhoni | Mn IManganese | Si Isilicon | P Iphosphorus | Cr Chromium | Nb+Ta I-Niobium-Tantalum | Co Cobalt | Mo Molybdenum | Fe Intsimbi | Al Aluminiyam | Ti I-Titanium | Ni Nickel |

| 0.10 ubuninzi | 0.50 ubuninzi | 0.50 ubuninzi | 0.015 ubuninzi | 20.0–23.0 | 3.15–4.15 | 1.0 ubuninzi | 8.0–10.0 | 5.0 ubuninzi | 0.40 ubuninzi | 0.40 ubuninzi | 58.0 imiz |

Ukunyamezelwa kweDimensional

| OD | OD Ukunyamezela | Unyamezelo eludongeni |

| .375”–0.500” ngaphandle | +.004”/-.000” | ± 10% |

| 0.500”–1.250” ngaphandle | +.005”/-.000” | ± 10% |

Iipropati zoomatshini

| Unikeze Amandla: | 60 ksi imiz |

| Tensile strength: | 120 ksi imiz |

| Ubude (umzuzu 2"): | 30% |

Iifoto zeFactory

Ukuhlolwa

Ukuthumela kunye nokuPakisha

Ingxelo yoVavanyo