Xa usenza kwi-progressive die, i-workpiece yoxinzelelo, iimeko zokucinezela kunye nezinto zokuqala zichaphazela amandla okufumana iziphumo ezizinzileyo zomzobo ngaphandle kwemibimbi.

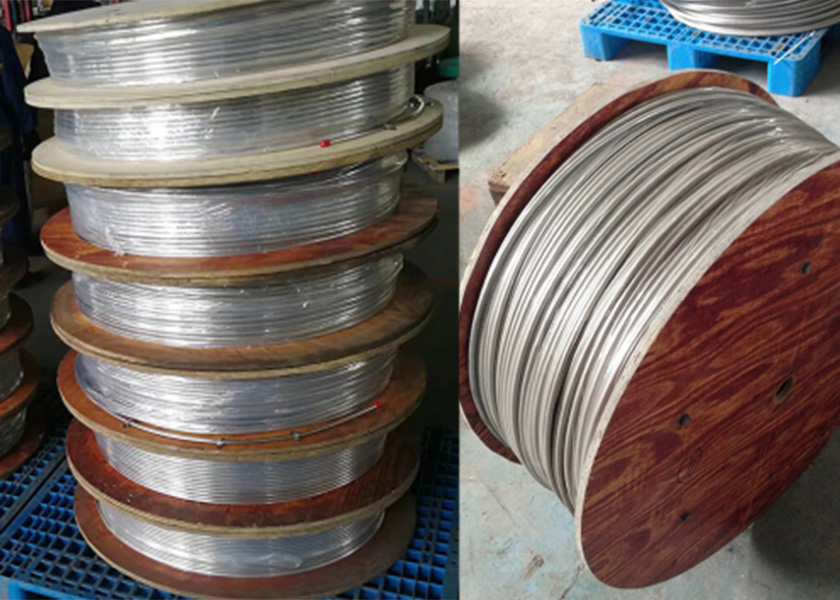

Q: Senza indebe ngentsimbi engama-304.Kwisikhululo sokuqala sokufa okuqhubekayo, sitsala malunga ne-0.75 intshi ubunzulu.Xa ndijonga ubukhulu beperimeter ye-butt flange, inokwahluka nge-intshi ezi-0.003 ukusuka kwelinye icala ukuya kwelinye.Ukubetha ngakunye kwahlukile kwaye akubonakali kwindawo enye.Ndaxelelwa ukuba inento yokwenza nokucutshungulwa kwezinto ezikrwada, mhlawumbi umphetho wangaphandle we-spool ephambili.Singayifumana njani ikomityi yokumila rhoqo ngaphandle kwamaqhekezana?

A: Ndiyabona ukuba umbuzo wakho ubuza imibuzo emibini: okokuqala kukwahluka okufumanayo kwinkqubo yokuzoba, kwaye okwesibini yimathiriyeli yomthombo kunye neenkcukacha zayo.

Ingxaki yokuqala sisiphene esisisiseko kuyilo lwesixhobo, ngoko makhe sidlule kwizinto ezisisiseko.Ukushwabana ngamaxesha athile kunye nokuguquguquka kobungqingqwa kwiiflange zendebe emva kokusolula kubonisa ukungonelanga kwezixhobo zokudibanisa kwisikhululo sakho sokusolula sokufa.Ngaphandle kokubona uyilo lwakho lokufa, kuya kufuneka ndicinge ukuba i-punch kunye ne-die radii kunye nococeko lwazo oluhlukeneyo luhlangabezana nazo zonke iiparamitha zoyilo oluqhelekileyo.

Ngethuba lenkqubo yokudweba, i-workpiece ibanjwe phakathi komzobo wokufa kunye nomnini we-edge, ngelixa i-punch yokudweba idonsa izinto eziphathekayo kwi-design die, idonsa kunye ne-radius yokudweba ukwenza igobolondo.Ukruthakruthwano olomeleleyo lwenzeka phakathi komngundo kunye nesibambi somsebenzi.Ngethuba le nkqubo, izinto eziphathekayo ziphantsi koxinzelelo olunqamlezileyo, olubangela ukushwabana kunye nokwelulwa kwe-radial njengoko umnini we-edge eyeka ukuhamba kwezinto.Ukuba uxinzelelo lokutywinwa luphezulu kakhulu, izinto eziphathekayo ziya kuphuka phantsi kwamandla okutsalwa kwepunch.Ukuba iphantsi kakhulu, imibimbi iya kuvela.

Umsebenzi womzobo ophumelelayo awukwazi ukudlula umda phakathi kwedayimitha yegobolondo kunye nobubanzi bomsebenzi.Lo mda uxhomekeke kubude bepesenti yezinto.Umgaqo jikelele kukupenda i-55% ukuya kwi-60% okokuqala kunye ne-20% ngexesha ngalinye emva koko.Kwikhiwane.I-1 ibonisa umgaqo oqhelekileyo wokubala uxinzelelo lwe-preform olufunekayo ukunweba (ndihlala ndongeza ubuncinane ubuncinane be-30% amandla angaphezulu njengento yokhuseleko. Oku kunokunciphisa ukuba kuyimfuneko, kodwa kunzima ukunyuka emva kokuba uyilo lugqityiwe).

Uxinzelelo lwe-billet p yi-2.5 N / mm2 yensimbi, i-2.0-2.4 N / mm2 ye-alloy yobhedu kunye ne-1.2-1.5 N / mm2 ye-aluminium alloy.

Umahluko kubukhulu beflange kungabonisa ukuba uyilo lwesixhobo sakho alomelelanga ngokwaneleyo.Isihlangu sokungunda kufuneka sibe ngqindilili ngokwaneleyo ukumelana noxinzelelo ngaphandle kokugoba.Inkxaso phantsi kwesihlangu kufuneka ibe yintsimbi eqinile, kwaye izikhonkwane zesikhokelo zezixhobo kufuneka zibe zikhulu ngokwaneleyo ukukhusela ukunyakaza kwecala lezixhobo eziphezulu kunye nezantsi ngexesha lokwelula.

Jonga nakwiindaba zakho.Ukuba izikhokelo zokushicilela zigugile kwaye zikhululekile, awuyi kuphumelela, kungakhathaliseki ukuba zinamandla kangakanani izixhobo zakho.Jonga i-press pusher ukuqinisekisa ukuba ichanekile kwaye isikwere kubo bonke ubude be-press stroke.Qinisekisa ukuba isithambisi sakho sokuzoba siyahluzwa kwaye sikwimeko entle, kwaye isixhobo sisebenzisa isixa esichanekileyo kunye nendawo echanekileyo yomlomo.Zonke izixhobo zokuprinta zihlolwe ngononophelo ukuze kuqinisekiswe ukugqitywa okufanelekileyo komphezulu, ukugubungela kunye nokulinganisa.Kwaye uhlawule ngokukodwa ukudweba i-radii, kufuneka babe nejometri epheleleyo kunye nokucoceka kwendawo.

Kwakhona, ngelixa abathengi bevame ukucinga ukuba i-304L kunye ne-304 eqhelekileyo iyatshintshana, i-304L lolona khetho lungcono lokwelula.I-L imele i-carbon ephantsi, enika i-304L i-0.2% amandla emveliso ye-35 KSI, ngelixa i-304 ine-0.2% yemveliso yamandla angama-42 KSI.Ngomlinganiselo we-16% wamandla emveliso ephantsi, i-304L idinga amandla amancinci okuguqula kunye nokubamba isikhunta ngexesha lokubumba.Kulula ukuyisebenzisa.

Are you concerned about stamping in the shop or about tools and dies? If so, send your questions to kateb@thefabricator.com and Thomas Vacca, CTO of Micro Co., will answer them.

STAMPING Journal kuphela kwempapasho yorhwebo enikelwe ngokukodwa kwiimfuno zentengiso yesitampu sesinyithi.Ukusukela ngo-1989, olu papasho lunikezelwe kubuchwephesha obuphambili, iindlela zeshishini, ezona ndlela zilungileyo kunye neendaba zokunceda iingcali zesitampu ziqhube ishishini labo ngokufanelekileyo.

Ufikelelo olupheleleyo lwedijithali kwi-FABRICATOR ngoku iyafumaneka, inika ufikelelo olulula kwimithombo yoshishino oluxabisekileyo.

Ufikelelo olupheleleyo lwedijithali kwi-Tube & Pipe Journal iyafumaneka ngoku, ibonelela ngokufikelela ngokulula kwizixhobo ezixabisekileyo zeshishini.

Yonwabela ufikelelo olupheleleyo lwedijithali kwi-STAMPING Journal, ijenali yentengiso yesitampu yesinyithi enenkqubela phambili yetekhnoloji yamva nje, ezona zenzo zibalaseleyo kunye neendaba zeshishini.

Ukufikelela ngokupheleleyo kwi-Fabricator en Español edition yedijithali ngoku iyafumaneka, inika ufikelelo olulula kwimithombo yoshishino oluxabisekileyo.

Kwinxalenye yokuqala yoluhlu lwethu olunamacandelo amabini, igcisa lesinyithi kunye newelder uRay Ripple ujoyina umamkeli uDan Davis…

Ixesha lokuposa: Jan-03-2023