I-Duplex Stainless Steel-Superduplex

Kwi-metallurgy, insimbi engenasici i-alloy yensimbi ene-chromium ubuncinane ye-10.5% kunye okanye ngaphandle kwezinye izinto ezixutywayo kunye nobuninzi be-1.2% yekhabhoni ngobunzima.Iintsimbi ezingenastainless, ezikwaziwa ngokuba yi-inox steels okanye i-inox esuka kwi-French inoxydable (inoxidizable)ialloys zentsimbiezaziwa kakhulu ngokuxhathisa kwazo ukubola, okonyuka ngokwanda komxholo wechromium.Ukumelana nokubola kunokwandiswa ngezongezo ze-nickel kunye ne-molybdenum.Ukuchasana kwezi ngxube zetsimbi kwimiphumo yeekhemikhali ze-corrosive agents zisekelwe kwi-passivation.Ukuze i-passivation yenzeke kwaye ihlale izinzile, i-alloy ye-Fe-Cr kufuneka ibe ne-chromium encinci ye-chromium malunga ne-10.5% ngobunzima, apho i-passivity ingenzeka kwaye ngaphantsi ayinakwenzeka.I-Chromium ingasetyenziselwa njengento enzima kwaye isetyenziswa rhoqo kunye ne-toughening element njenge-nickel ukuvelisa iimpawu eziphezulu zoomatshini.

Duplex Steel engatyiwa

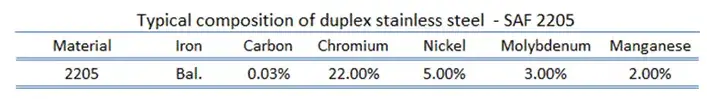

Njengoko igama labo libonisa, i-Duplex steels stainless yindibaniselwano yeentlobo ezimbini eziphambili ze-alloy.Bane-microstructure edibeneyo ye-austenite kunye ne-ferrite, injongo ngokuqhelekileyo kukuvelisa umxube we-50/50, nangona, kwii-alloys zorhwebo, umlinganiselo unokuba ngu-40/60.Ukuxhathisa kwabo kwe-corrosion kufana noogxa babo be-austenitic, kodwa ukuxhathisa kwabo uxinzelelo-i-corrosion (ingakumbi kwi-chloride yoxinzelelo lwe-corrosion cracking), amandla okuqina, kunye namandla okuvelisa (ngokuphindwe kabini amandla emveliso ye-austenitic stainless steels) ngokuqhelekileyo iphezulu kune-austenitic. amabanga.Kwi-duplex steel stainless, i-carbon igcinwa kumanqanaba aphantsi kakhulu (C <0.03%).Umxholo we-Chromium usuka kwi-21.00 ukuya kwi-26.00%, umxholo we-nickel usuka kwi-3.50 ukuya kwi-8.00%, kwaye ezi ngxube zinokuba ne-molybdenum (ukuya kwi-4.50%).Ukuqina kunye ne-ductility ngokubanzi ziwela phakathi kwamanqanaba e-austenitic kunye ne-ferritic.Amabakala e-Duplex ahlala ahlulahlulwe abe ngamaqela amancinci amathathu ngokusekwe ekuxhathiseni ukubola: i-lean duplex, i-standard duplex, kunye ne-superduplex.Iintsimbi ze-Superduplex zongeze amandla kunye nokuchasana nazo zonke iintlobo zokubola xa kuthelekiswa neentsimbi eziqhelekileyo ze-austenitic.Ukusetyenziswa okuqhelekileyo kubandakanya izicelo zaselwandle, izityalo zepetrochemical, izityalo zokukhupha ityuwa, abatshintshi bobushushu, kunye neshishini lokwenza iphepha.Namhlanje, i-oyile kunye ne-gas industry ngoyena msebenzisi mkhulu kwaye uye watyhala amabakala anganyangekiyo kwi-corrosion, ekhokelela kuphuhliso lweentsimbi ze-superduplex.

Ukuchasana kwensimbi engenasici kwimiphumo yeekhemikhali ze-corrosive agents zisekelwe kwi-passivation.Ukuze i-passivation yenzeke kwaye ihlale izinzile, i-alloy ye-Fe-Cr kufuneka ibe ne-chromium encinci ye-chromium malunga ne-10.5% ngobunzima, apho i-passivity ingenzeka kwaye ngaphantsi ayinakwenzeka.I-Chromium ingasetyenziselwa njengento enzima kwaye isetyenziswa rhoqo kunye ne-toughening element njenge-nickel ukuvelisa iimpawu eziphezulu zoomatshini.

I-Duplex Stainless Steels - SAF 2205 - 1.4462

I-duplex eqhelekileyo yensimbi engenasici yi-SAF 2205 (i-trademark ye-Sandvik ye-22Cr duplex (i-ferritic-austenitic) insimbi engenasici), ehlala iqulethe i-22% ye-chromium kunye ne-5% nickel.Inokumelana nokugqwesa okugqwesileyo kunye namandla aphezulu, i-2205 yeyona nto isetyenziswa kakhulu i-duplex steel stainless.Izicelo ze-SAF 2205 zikula mashishini alandelayo:

- Uthutho, ukugcinwa, kunye nokulungiswa kweekhemikhali

- Izixhobo zokusebenza

- I-chloride ephezulu kunye neendawo zaselwandle

- Ukuhlola i-oyile negesi

- Oomatshini bephepha

IiPropati zeDuplex Steel engatyiwa

Iipropati zezinto eziphathekayo ziipropati ezinzulu, oku kuthetha ukuba zizimeleyo kubungakanani bobunzima kwaye zinokwahluka kwiindawo ngeendawo ngaphakathi kwenkqubo nangaliphi na ixesha.Inzululwazi yemathiriyeli ibandakanya ukufunda ubume bemathiriyeli kunye nokunxulumanisa neempawu zazo (oomatshini, umbane, njl. njl.).Nje ukuba inzululwazi yezixhobo ikwazi malunga nolu lungelelwaniso lwepropathi, banokuqhubeka bafunde ukusebenza okuhambelanayo kwemathiriyeli kwisicelo esinikiweyo.Ezona zigqibo ziphambili zesakhiwo semathiriyeli kwaye ke iipropathi zayo zizinto zayo zekhemikhali eziyinxalenye kunye nendlela eqhutywe ngayo kwimo yayo yokugqibela.

IiPropati zoomatshini beNtsimbi yeDuplex eNyintsi

Izinto eziphathekayo zikhethwa rhoqo kwizicelo ezahlukeneyo ngenxa yokuba zineendibaniselwano ezinqwenelekayo zeempawu zoomatshini.Ukusetyenziswa kolwakhiwo, iipropathi zezinto eziphathekayo zibalulekile kwaye iinjineli kufuneka zizithathele ingqalelo.

Amandla eNtsimbi yeDuplex

Kwi-mechanics yezinto eziphathekayo, iamandla esixhobokukukwazi ukumelana nomthwalo osetyenzisiweyo ngaphandle kokusilela okanye ukuguqulwa kweplastiki.Amandla ezinto eziphathekayo aqwalasela ubudlelwane phakathi kwemithwalo yangaphandle esetyenziswe kwizinto eziphathekayo kunye nokuguqulwa kwesiphumo okanye utshintsho kwimilinganiselo yezinto eziphathekayo.Amandla ezinto eziphathekayo kukukwazi ukumelana nalo mthwalo osetyenzisiweyo ngaphandle kokungaphumeleli okanye ukuguqulwa kweplastiki.

Ukomelela kokugqibela kokuqina

Amandla okugqibela entsimbi ye-duplex stainless steel-SAF 2205 yi-620 MPa.

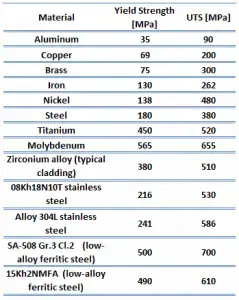

Iamandla okugqibelayeyona iphezulu kubunjineliijika loxinzelelo-strain.Oku kuhambelana noxinzelelo oluphezulu olugcinwe yisakhiwo kuxinzelelo.Amandla okuqina okugqibela ahlala efinyezwa "kumandla okuqina" okanye "okugqibeleleyo."Ukuba olu xinzelelo luyasetyenziswa kwaye lugcinwe, ukuphuka kuya kubangela.Rhoqo, eli xabiso libaluleke kakhulu kunoxinzelelo lwesivuno (ubungakanani bepesenti ezingama-50 ukuya kuma-60 ngaphezulu kwemveliso yezinye iindidi zesinyithi).Xa i-ductile material ifikelela kumandla ayo okugqibela, ifumana i-necking apho indawo ye-cross-sectional inciphisa kwindawo.Ijika le-stress-strain curve ayinalo uxinzelelo oluphezulu kunamandla okugqibela.Nangona ukukhubazeka kunokuqhubeka nokukhula, uxinzelelo luhlala luyancipha emva kokufumana amandla okugqibela.Yipropati ebanzi kakhulu;ngoko ke, ixabiso layo alixhomekeke kubungakanani bomzekelo wovavanyo.Nangona kunjalo, kuxhomekeke kwezinye izinto, ezinjengokulungiswa komzekelo, ubukho okanye ngenye indlela yeziphene zomhlaba, kunye nobushushu bommandla wovavanyo kunye nezinto eziphathekayo.Amandla okuqina okugqibela ahluka ukusuka kwi-50 MPa ye-aluminiyam ukuya phezulu njenge-3000 MPa yentsimbi ephezulu kakhulu.

Iamandla okugqibelayeyona iphezulu kubunjineliijika loxinzelelo-strain.Oku kuhambelana noxinzelelo oluphezulu olugcinwe yisakhiwo kuxinzelelo.Amandla okuqina okugqibela ahlala efinyezwa "kumandla okuqina" okanye "okugqibeleleyo."Ukuba olu xinzelelo luyasetyenziswa kwaye lugcinwe, ukuphuka kuya kubangela.Rhoqo, eli xabiso libaluleke kakhulu kunoxinzelelo lwesivuno (ubungakanani bepesenti ezingama-50 ukuya kuma-60 ngaphezulu kwemveliso yezinye iindidi zesinyithi).Xa i-ductile material ifikelela kumandla ayo okugqibela, ifumana i-necking apho indawo ye-cross-sectional inciphisa kwindawo.Ijika le-stress-strain curve ayinalo uxinzelelo oluphezulu kunamandla okugqibela.Nangona ukukhubazeka kunokuqhubeka nokukhula, uxinzelelo luhlala luyancipha emva kokufumana amandla okugqibela.Yipropati ebanzi kakhulu;ngoko ke, ixabiso layo alixhomekeke kubungakanani bomzekelo wovavanyo.Nangona kunjalo, kuxhomekeke kwezinye izinto, ezinjengokulungiswa komzekelo, ubukho okanye ngenye indlela yeziphene zomhlaba, kunye nobushushu bommandla wovavanyo kunye nezinto eziphathekayo.Amandla okuqina okugqibela ahluka ukusuka kwi-50 MPa ye-aluminiyam ukuya phezulu njenge-3000 MPa yentsimbi ephezulu kakhulu.

Unikeze Amandla

Amandla esivuno se-duplex yensimbi engenasici - i-SAF 2205 yi-440 MPa.

Iinqaku lesivunoyingongoma eku aijika loxinzelelo-strainoko kubonisa umda wokuziphatha okulastiki kunye nokuziphatha kweplastiki yokuqala.Amandla esivuno okanye uxinzelelo lwesivuno yipropathi ephathekayo echazwa njengoxinzelelo apho into iqala ukonakala ngokweplastiki.Ngokwahlukileyo, inqaku lesivuno yindawo apho i-nonlinear (elastic + plastic) deformation iqala.Ngaphambi komlinganiselo wesivuno, izinto eziphathekayo ziya kuguqula i-elastically kwaye zibuyele kwisimo sayo sokuqala xa uxinzelelo olusetyenzisiweyo lususiwe.Emva kokuba indawo yokuvelisa idluliselwe, inxalenye ethile ye-deformation iya kuba yesigxina kwaye ayinakubuyela umva.Ezinye iintsimbi kunye nezinye izixhobo zibonisa indlela yokuziphatha ebizwa ngokuba yimveliso yenqaku.Amandla esivuno ayahluka ukusuka kwi-35 MPa ye-aluminium yamandla aphantsi ukuya kuthi ga kwi-1400 MPa yentsimbi ephezulu.

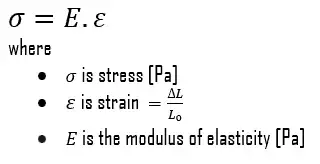

Imodulus eNcinci yoKulula

Imodyuli encinci ye-elasticity ye-duplex steel stainless-SAF 2205 yi-200 GPa.

Imodyuli encinci yokuqinayimodyuli enwebekayo yokuqina kunye noxinzelelo olucinezelayo kwi-linear elasticity regime ye-uniaxial deformation kwaye idla ngokuvavanywa ngovavanyo lwe-tensile.Ukuya kuthi ga ekunciphiseni uxinzelelo, umzimba uya kukwazi ukubuyisela imilinganiselo yawo ekususweni komthwalo.Uxinzelelo olusetyenzisiweyo lubangela ukuba iiathom ezikwikristale zihambe ukusuka kwindawo yazo elinganayo, kunye nazo zonkeiiathombasuswa kwindawo efanayo kwaye bagcine ijometri yabo ehambelanayo.Xa uxinzelelo lususiwe, zonke iiathom zibuyela kwiindawo zazo zangaphambili, kwaye akukho deformation esisigxina eyenzekayo.Ngoku kaUmthetho kaHooke, uxinzelelo lulingana noxinzelelo (kwindawo e-elastic), kunye ne-slope yi-Young's modulus.Imodyuli encinci ilingana noxinzelelo lwelongitudinal olwahlulwe luxinzelelo.

Ukuqina kweDuplex Stainless Steel

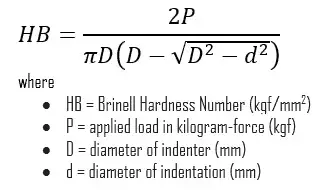

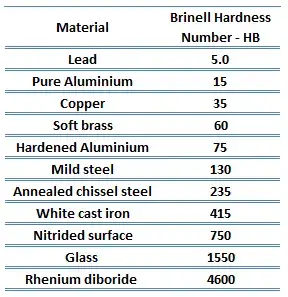

Ubulukhuni beBrinell yeensimbi ezingenasici ze-duplex - i-SAF 2205 imalunga ne-217 MPa.

Kwisayensi yezinto,ubulukhunikukwazi ukumelana nokungeniswa komphezulu (ukuguqulwa kweplastiki yendawo) kunye nokukrwela.Ukuqina mhlawumbi yeyona propati yemathiriyeli engachazwanga kakuhle kuba inokubonisa ukuxhathisa ukukrwela, ukukrazuka, ukujikela, okanye ukuxhathisa ukumila okanye ukuguquka kweplastiki yendawo.Ubunzima bubalulekile ngokwembono yobunjineli kuba ukuxhathisa ukunxitywa okanye ukukhukuliseka okanye ukukhukuliseka komphunga, i-oyile, kunye namanzi ngokubanzi kuyenyuka ngobulukhuni.

Kwisayensi yezinto,ubulukhunikukwazi ukumelana nokungeniswa komphezulu (ukuguqulwa kweplastiki yendawo) kunye nokukrwela.Ukuqina mhlawumbi yeyona propati yemathiriyeli engachazwanga kakuhle kuba inokubonisa ukuxhathisa ukukrwela, ukukrazuka, ukujikela, okanye ukuxhathisa ukumila okanye ukuguquka kweplastiki yendawo.Ubunzima bubalulekile ngokwembono yobunjineli kuba ukuxhathisa ukunxitywa okanye ukukhukuliseka okanye ukukhukuliseka komphunga, i-oyile, kunye namanzi ngokubanzi kuyenyuka ngobulukhuni.

Uvavanyo lobulukhuni beBrinelllolunye lweemvavanyo zobulukhuni bokujinga eziphuhliselwe uvavanyo lokuqina.Kwiimvavanyo ze-Brinell, i-indenter eqinile, engqukuva inyanzeliswa phantsi komthwalo othile kumphezulu wentsimbi ukuze ivavanywe.Uvavanyo oluqhelekileyo lusebenzisa i-10 mm (0.39 in) ububanzi bebhola yentsimbi eqinile njenge-indenter ene-3,000 kgf (29.42 kN; 6,614 lbf) amandla.Umthwalo ugcinwa rhoqo ngexesha elithile (phakathi kwe-10 kunye ne-30 s).Kwizinto ezithambileyo, kusetyenziswe amandla amancinci;kwizinto ezinzima, ibhola ye-tungsten carbide ithathelwa indawo yebhola yensimbi.

Uvavanyo lubonelela ngeziphumo zamanani ukulinganisa ubulukhuni bezinto eziphathekayo, ezibonakaliswa yinombolo yobunzima beBrinell - HB.Inombolo yobunzima beBrinell ichongwe yimigangatho yovavanyo esetyenziswa ngokuqhelekileyo (ASTM E10-14 [2] kunye ne-ISO 6506–1: 2005) njenge-HBW (H ukusuka kubunzima, B ukusuka kuBrinell, kunye ne-W ukusuka kwizinto ze-indenter, i-tungsten (wolfram) carbide).Kwimigangatho yangaphambili, i-HB okanye i-HBS yayisetyenziselwa ukubhekisela kwimilinganiselo eyenziwe ngee-identers zensimbi.

Inombolo yobunzima beBrinell (HB) ngumthwalo owahlulwe ngomphezulu wendawo yokuhlenga-hlengisa.Ububanzi bombonakaliso bulinganiswa nge-microscope enezinga eliphezulu.Inombolo yokuqina kweBrinell ibalwa ukusuka kwinxaki:

Kukho iindlela ezahlukeneyo zovavanyo ezisetyenziswa ngokufanayo (umzekelo, iBrinell,Knoop,Vickers, kwayeRockwell).Kukho iitheyibhile ezikhoyo ezinxibelelanisa amanani obunzima kwiindlela ezahlukeneyo zovavanyo apho ulungelelwaniso lusebenza khona.Kuzo zonke izikali, inani lobunzima obuphezulu limele isinyithi esinzima.

IiPropati zeThermal zeDuplex Steel engatyiwa

Iimpawu ze-Thermal zezixhobo zibhekisela kwimpendulo yezixhobo kwiinguqu zaboubushushukunye nokusetyenziswa kweubushushu.Njengesiqina sifunxaamandlangendlela yobushushu, ubushushu balo buyanda, kwaye imilinganiselo yayo iyanda.Kodwa izinto ezahlukeneyo zisabela ngokusetyenziswa kobushushu ngokwahlukileyo.

Umthamo wobushushu,ukwanda kwe-thermal, kwayeconductivity thermalzisoloko zibalulekile kusetyenziso lwento eqinileyo.

Indawo yokunyibilika yeNtsimbi yeDuplex

Indawo yokunyibilika ye-duplex steel stainless-SAF 2205 steel ijikeleze i-1450 ° C.

Ngokubanzi, ukunyibilika lutshintsho lwesigaba sento ukusuka kwisiqina ukuya kwisigaba solwelo.IIndawo yokunyibilikaInto liqondo lobushushu apho olu tshintsho lwenzeka khona.Indawo yokunyibilika ikwachaza imeko apho okuqinileyo kunye nolwelo lunokubakho ngokulinganayo.

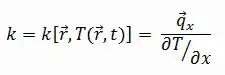

I-Thermal Conductivity ye-Duplex Stainless Steel

I-thermal conductivity ye-duplex stainless steels - SAF 2205 yi-19 W / (m. K).

Iimpawu zokutshintsha ubushushu bezinto eziqinileyo zilinganiswa ngepropathi ebizwa ngokuba yiconductivity thermal, k (okanye λ), ilinganiswa nge-W/mK Ilinganisa ukukwazi kwento ukuhambisa ubushushu ngesixhoboukuqhuba.Qaphela okoUmthetho kaFourierisebenza kuwo wonke umba, nokuba ikwimeko enjani (iqinile, engamanzi, okanye irhasi).Ke ngoko, ikwachazwa kulwelo kunye neegesi.

Iconductivity thermalkulwelo oluninzi kunye nezinto eziqinileyo ziyahluka ngokweqondo lobushushu, kwaye kumphunga, kukwaxhomekeke kuxinzelelo.Nje:

Iimathiriyeli ezininzi ziphantse zafana, ngoko ke sinokubhala u-k = k (T).Iinkcazo ezifanayo zihambelana ne-thermal conductivities kwi-y- kunye ne-z-directions (ky, kz), kodwa kwizinto ezibonakalayo ze-isotropic, i-thermal conductivity ixhomekeke kwindlela yokudlulisa, kx = ky = kz = k.

Ixesha lokuposa: Feb-04-2023