Iimeko zilinganiselwe ixesha lokusebenza

Ukusetyenziswa okuqhelekileyo okudinga izinto eziphindwe kabini ukuba zivezwe kwiimeko eziphakamileyo zokushisa ziinqanawa zoxinzelelo, i-fan blades / i-impellers okanye i-exhaust gas scrubbers.Iimfuno zezinto eziphathekayo zinokuvela kumandla aphezulu omatshini ukuya kwi-corrosion resistance.Ukwakheka kweekhemikhali zamabakala axutyushwa kweli nqaku zidweliswe kwiThebhile 1.

Ukubola kweSpinodal

Ukubola kweSpinodal (ekwabizwa ngokuba yi-demixing okanye ngokwembali njenge-475 °C-embrittlement) luhlobo lokwahlukana kwesigaba kwisigaba se-ferritic, esenzeka kumaqondo obushushu amalunga nama-475 °C.Esona siphumo sivakaliswa kakhulu lutshintsho kwi-microstructure, ebangela ukubunjwa kwesigaba sika-α´, esikhokelela ku-embrittlement yezinto.Oku, kwakhona, kunciphisa ukusebenza kwemveliso yokugqibela.

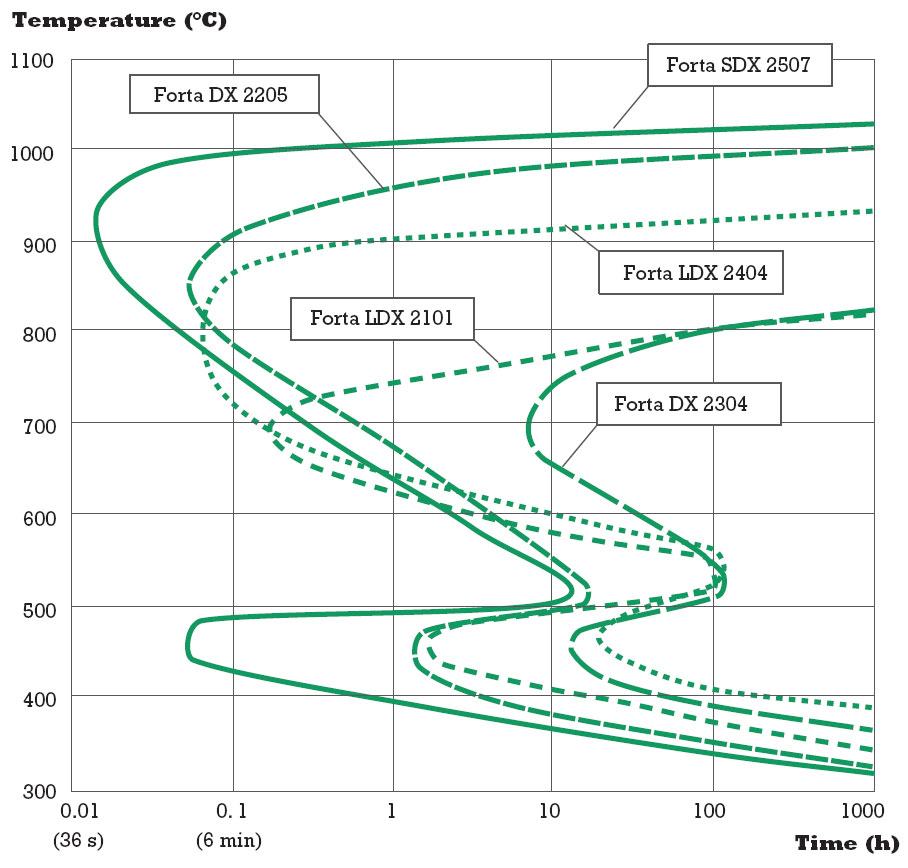

Umzobo we-1 ubonisa umzobo wexesha lokutshintsha kweqondo lokushisa (TTT) kwi-duplex materials ezifundiweyo, kunye nokubola kwe-spinodal emelelwe kummandla we-475 °C.Kufuneka kuqatshelwe ukuba lo mzobo we-TTT umele ukuncipha kobulukhuni ngama-50% xa kuthelekiswa novavanyo lokuqina kwempembelelo kwiisampulu zeCharpy-V, edla ngokuvunywa njengebonisa ukuqina.Kwezinye izicelo ukuhla okukhulu kokuqina kunokwamkeleka, nto leyo etshintsha ubume bomzobo we-TTT.Ngoko ke, isigqibo sokuseta ubuninzi be-OT sixhomekeke kwinto ethathwa ngokuba yinqanaba elamkelekileyo le-embrittlement, oko kukuthi, ukunciphisa ukuqina kwemveliso yokugqibela.Kufuneka kukhankanywe ukuba ii-TTT-graphs zembali nazo zaveliswa ngokusebenzisa i-threshold ebekiwe, njenge-27J.

Amanqaku aphezulu adibeneyo

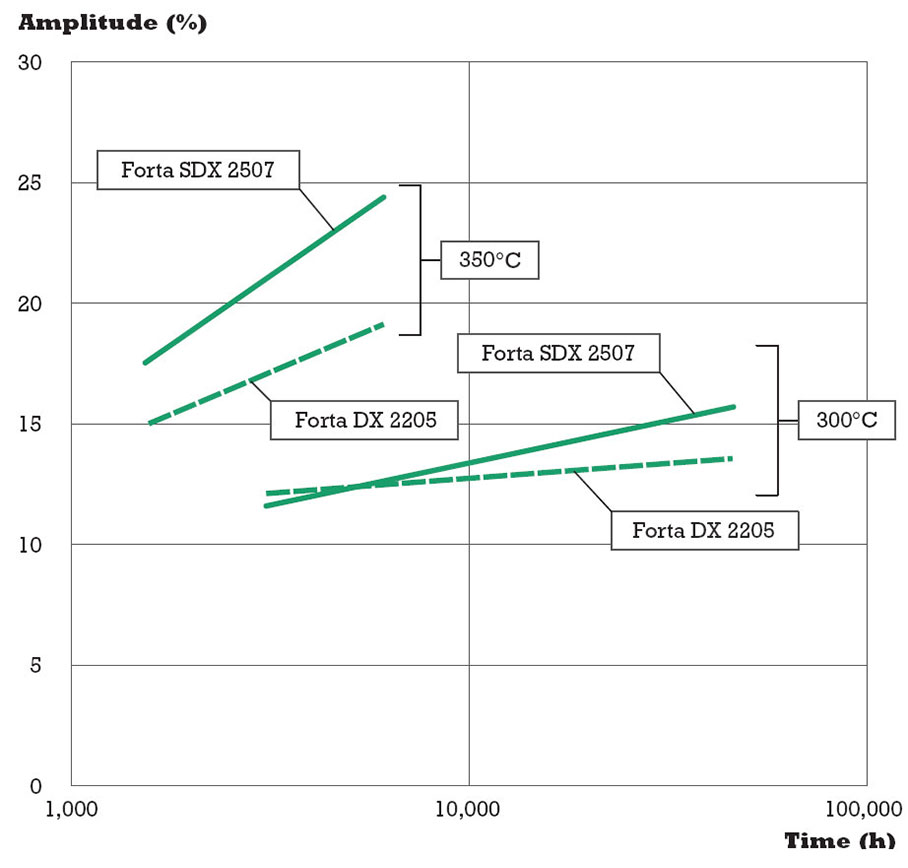

Umzobo 1 ubonisa ukuba ukonyuka kwezinto ezidibeneyo ukusuka kwibakala le-LDX 2101 ukuya kwibakala le-SDX 2507 kukhokelela kwisantya sokubola ngokukhawuleza, ngelixa i-lean duplex ibonisa ukuqala kokulibaziseka kokubola.Impembelelo yezinto ezixutywayo ezifana ne-chromium (Cr) kunye ne-nickel (Ni) kwi-spinodal decomposition kunye ne-embrittlement iboniswe ngophando lwangaphambili. inyusiwe ukusuka kwi-300 ukuya kwi-350 °C kwaye ikhawuleza kakhulu kwibakala eliphezulu le-alloyi ehlanganisiweyo ye-SDX 2507 kune-DX 2205 engaphantsi.

Oku kuqonda kunokubaluleka ekuncedeni abathengi bathathe isigqibo malunga ne-OT ephezulu efanelekileyo kwibakala abakhethiweyo kunye nokusetyenziswa.

Ukumisela ubushushu obukhulu

Njengoko bekutshiwo ngaphambili, ubuninzi be-OT ye-duplex imathiriyeli inokusetwa ngokokwehla okwamkelekileyo kukuqina kwempembelelo.Ngokuqhelekileyo, i-OT ehambelana nexabiso le-50% yokunciphisa ubunzima iyamkelwa.

I-OT ixhomekeke kwixesha kunye nexesha

I-slope kwimisila yeegophe kumzobo we-TTT kuMzobo 1 ubonisa ukuba ukubola kwe-spinodal akwenzeki kuphela kwiqondo lokushisa elinye kunye nokuyeka ngaphantsi kwelo nqanaba.Endaweni yoko, yinkqubo engaguqukiyo xa imathiriyeli ephindwe kabini ibekwe kubushushu bokusebenza obungaphantsi kwe-475 °C.Kukwacacile kananjalo ukuba, ngenxa yamazinga asezantsi osasazo, amaqondo obushushu asezantsi athetha ukubola kuya kuqala emva kwexesha kwaye kuqhubeke kancinci kakhulu.Ke ngoko, ukusebenzisa imathiriyeli ephindwe kabini kumaqondo obushushu asezantsi akunakubangela iingxaki iminyaka okanye amashumi eminyaka.Ukanti okwangoku kukho utyekelo lokuseta ubuninzi beOT ngaphandle kokuqwalaselwa kwexesha lokuvezwa.Umbuzo obalulekileyo ke ngoko yintoni indibaniselwano yexesha lokushisa kufuneka isetyenziswe ukugqiba ukuba kukhuselekile ukusebenzisa izinto eziphathekayo okanye cha?U-Herzman et al.10 ushwankathela le ngxaki kakuhle: “…Ukusetyenziswa kuya kuthi ke kuthintelwe kumaqondo obushushu apho i-kinetics of demixing isezantsi kakhulu kangangokuba ayinakwenzeka ngexesha lobugcisa obuyiliweyo bemveliso…”.

Impembelelo ye-welding

Uninzi lwezicelo zisebenzisa i-welding ukujoyina amacandelo.Kuyaziwa ukuba i-weld microstructure kunye ne-chemistry yayo iyahluka kwizinto ezisisiseko ze-3.Ngokuxhomekeke kwizinto zokuzalisa, ubuchule be-welding kunye neeparitha ze-welding, i-microstructure ye-welds ihluke kakhulu kwizinto ezininzi.I-microstructure ikholisa ukuba rhabaxa, kwaye oku kuquka nobushushu obuphezulu bobushushu bommandla ochaphazelekayo (HTHAZ), obuchaphazela ukubola kwespinodal kwi weldments.Ukwahluka kwe-microstructure phakathi kobuninzi kunye ne-weldments sisihloko esihlaziywe apha.

Ukushwankathela imiba ethintelayo

Amacandelo angaphambili akhokelela kwezi zigqibo zilandelayo:

- Zonke izixhobo eziphindwe kabini ziphantsi komxholo

Ukubola kwespinodal kumaqondo obushushu amalunga nama-475 °C. - Ngokuxhomekeke kumxholo we-alloying, isantya sokubola ngokukhawuleza okanye esincinci silindeleke.I-Higher Cr kunye ne-Ni content ikhuthaza ukuxutywa ngokukhawuleza.

- Ukuseta ubushushu obuphezulu bokusebenza:

– Ukudibanisa ixesha lokusebenza kunye nobushushu kufuneka kuthathelwe ingqalelo.

– Inqanaba elamkelekileyo lokuhla kokuqina, oko kukuthi, umgangatho onqwenelekayo wokuqina kokugqibela kufuneka umiselwe - Xa iinqununu ezongezelelweyo ze-microstructural, ezifana ne-welds, zingeniswa, i-OT ephezulu inqunywe yinxalenye ebuthakathaka.

Imigangatho yehlabathi

Imigangatho emininzi yaseYurophu naseMelika iye yaphononongwa kule projekthi.Bagxininise kwizicelo kwiinqanawa zoxinzelelo kunye namacandelo emibhobho.Ngokubanzi, ukungafani malunga ne-OT ekhuthazwayo ephezulu phakathi kwemigangatho ehlaziyiweyo inokwahlulwa ibe yimbono yaseYurophu neMelika.

Imigangatho yokucaciswa kwemathiriyeli yaseYurophu yeentsimbi ezingenastainless (umz. EN 10028-7, EN 10217-7) ithetha ubuninzi be-OT ye-250 °C ngenyaniso yokuba iipropati zemathiriyeli zibonelelwa kuphela ukuya kutsho kobu bushushu.Ngaphezu koko, imigangatho yoyilo lwaseYurophu kwiinqanawa zoxinzelelo kunye nemibhobho (EN 13445 kunye ne-EN 13480, ngokulandelanayo) ayiniki naluphi na ulwazi olongezelelweyo malunga ne-OT ephezulu ukusuka kwinto enikeziweyo kwimigangatho yabo yempahla.

Ngokwahlukileyo, i-American material specication (umz. ASME SA-240 ye-ASME icandelo II-A) ayibonisi naziphi na iinkcukacha zobushushu obuphakamileyo kwaphela.Le datha endaweni yoko inikezelwe kwicandelo le-ASME II-D, 'IiProperties', exhasa iikhowudi zokwakha ngokubanzi kwiinqanawa zoxinzelelo, icandelo le-ASME VIII-1 kunye ne-VIII-2 (eli lokugqibela linikezela indlela yoyilo oluphezulu).Kwi-ASME II-D, ubuninzi be-OT buchazwe ngokucacileyo njenge-316 °C kwii-alloys ezininzi eziphindwe kabini.

Ukusetyenziswa kwemibhobho yoxinzelelo, zombini imithetho yoyilo kunye neepropati eziphathekayo zinikwe kwi-ASME B31.3.Kule khowudi, idatha yomatshini inikezelwa kwi-duplex alloys ukuya kwi-316 °C ngaphandle kwenkcazo ecacileyo ye-OT ephezulu.Nangona kunjalo, unokutolika ulwazi ukuthobela oko kubhalwe kwi-ASME II-D, kwaye ke, eyona OT iphezulu yemigangatho yaseMelika kwiimeko ezininzi yi-316 °C.

Ukongeza kolona lwazi luphezulu lwe-OT, imigangatho yomibini yaseMelika neyaseYurophu ithetha ukuba kukho umngcipheko wokudibana ne-embrittlement kumaqondo obushushu anyukileyo (>250 °C) ngamaxesha okuvezwa amade, ekufuneka ke aqwalaselwe kuyilo kunye nesigaba senkonzo.

Kwi-welds, imigangatho emininzi ayenzi naziphi na iinkcazo eziqinileyo kwimpembelelo yokubola kwe-spinodal.Nangona kunjalo, eminye imigangatho (umz. ASME VIII-1, Itheyibhile UHA 32-4) ibonisa ukuba kunokwenzeka ukwenza unyango oluthile lobushushu emva kwe-weld.Ezi zinto azifunwa kwaye azivumelekanga, kodwa xa zizenza kufuneka zenziwe ngokweeparamitha ezibekwe kwangaphambili kumgangatho.

Okuthethwa lishishini

Ulwazi oluveliswe ngabanye abavelisi abaninzi be-duplex stainless steel luye lwaphononongwa ukuze lubone ukuba banxibelelana ngantoni na malunga nomgangatho wobushushu kumabakala abo.I-2205 ilinganiselwe kwi-315 °C yi-ATI, kodwa i-Acerinox ibeka i-OT kwibakala elifanayo kwi-250 °C kuphela.Le yimida ephezulu kunye nesezantsi ye-OT yebanga le-2205, ngelixa phakathi kwazo ezinye ii-OTs zixhunyaniswa ne-Aperam (300 ° C), i-Sandvik (280 ° C) kunye ne-ArcelorMittal (280 ° C).Oku kubonisa ukunaba kwee-OTs ezicetyisiweyo eziphezulu kwibakala elinye eliya kuba neepropati ezithelekiseka kakhulu ukusuka kumenzi ukuya kumenzi.

Isizathu sangasemva sokuba kutheni umenzi esete i-OT ethile ayisoloko ityhilwa.Kwiimeko ezininzi, oku kusekelwe kumgangatho omnye.Imigangatho eyahlukeneyo inxibelelana ne-OTs ezahlukeneyo, ngoko ke ukusasazeka kwamaxabiso.Isigqibo esinengqiqo kukuba iinkampani zaseMelika zibeka ixabiso eliphezulu ngenxa yeengxelo kumgangatho we-ASME, ngelixa iinkampani zaseYurophu zibeka ixabiso eliphantsi ngenxa yomgangatho we-EN.

Bafuna ntoni abathengi?

Ngokuxhomekeke kwisicelo sokugqibela, imithwalo eyahlukeneyo kunye nokuvezwa kwezinto eziphathekayo kulindeleke.Kule projekthi, i-embrittlement ngenxa yokubola kwe-spinodal yayinomdla kakhulu njengoko isebenza kakhulu kwiinqanawa zoxinzelelo.

Nangona kunjalo, kukho usetyenziso olwahlukeneyo olubonisa amabanga amabini ukuya kwimithwalo ephakathi koomatshini kuphela, njenge-scrubbers11-15.Esinye isicelo sasinxulumene ne-fan blades kunye ne-impellers, ezivezwe kwimithwalo yokudinwa.Uncwadi lubonisa ukuba i-spinodal decomposition iziphatha ngendlela eyahlukileyo xa umthwalo wokukhathala usetyenziswa15.Ngeli nqanaba, kuyacaca ukuba i-OT ephezulu yezi zicelo ayikwazi ukusetwa ngendlela efanayo kwiinqanawa zoxinzelelo.

Olunye udidi lwezicelo zezezicelo ezinxulumene nomhlwa kuphela, ezifana nezikhuhla zegesi ephuma elwandle.Kule meko, ukuxhatshazwa kwe-corrosion kubaluleke kakhulu kunomda we-OT phantsi komthwalo womatshini.Nangona kunjalo, zombini izinto zinefuthe ekusebenzeni kwemveliso yokugqibela, ekufuneka ithathelwe ingqalelo xa ibonakalisa eyona OT iphezulu.Kwakhona, eli tyala lahlukile kumatyala amabini angaphambili.

Ngokubanzi, xa ucebisa umthengi nge-OT ephezulu efanelekileyo kwibakala labo le-duplex, uhlobo lwesicelo lubaluleke kakhulu ekuseteni ixabiso.Oku kubonisa ngakumbi ubunzima bokumisela i-OT eyodwa kwibakala, njengoko indawo apho izinto ezisetyenzisiweyo zinefuthe elibalulekileyo kwinkqubo yokuqhawula.

Yintoni ubushushu obuphezulu bokusebenza kwi-duplex?

Njengoko kukhankanyiwe, ubushushu obuphezulu bokusebenza bubekwe yi-kinetics ephantsi kakhulu yokubola kwe-spinodal.Kodwa silinganisa njani lo bushushu kwaye yintoni kanye kanye "i-kinetics ephantsi"?Impendulo kumbuzo wokuqala ilula.Sele sitshilo ukuba imilinganiselo yokuqina iqhele ukwenziwa ukuqikelela izinga kunye nenkqubela phambili yokubola.Oku kusekwe kwimigangatho elandelwa ngabakhiqizi abaninzi.

Umbuzo wesibini, malunga noko kuthethwa ngeekinetics eziphantsi kunye nexabiso apho sibeka khona umda weqondo lokushisa kunzima ngakumbi.Oku kungenxa yokuba iimeko zomda wobushushu obuninzi zihlanganiswe ukusuka kokubini ubushushu obuphezulu (T) ngokwayo kunye nexesha lokusebenza (t) apho obu bushushu bugcinwe khona.Ukuqinisekisa le ndibaniselwano ye-Tt, utoliko olwahlukeneyo lokuqina “kuphantsi” kungasetyenziswa:

• Umda osezantsi, omiselwe ngokwembali nonokuthi usetyenziswe kwiiwelds yi-27 Joules (J)

• Phakathi kwemigangatho ubukhulu becala i-40J imiselwe njengomda.

• I-50% yehla kukuqina kokuqala ikwasetyenziswa rhoqo ukuseta umda osezantsi.

Oku kuthetha ukuba isitatimenti sobuninzi be-OT kufuneka sisekelwe ubuncinane kwiingcamango ezintathu ekuvunyelwene ngazo:

• Ukubonakaliswa kwexesha lobushushu kwemveliso yokugqibela

• Elona xabiso liphantsi elamkelekileyo lokuqina

• Indawo yokugqibela yesicelo (ikhemistri kuphela, umthwalo woomatshini ewe/hayi njalo njalo.)

Ulwazi oludityanisiweyo lokulinga

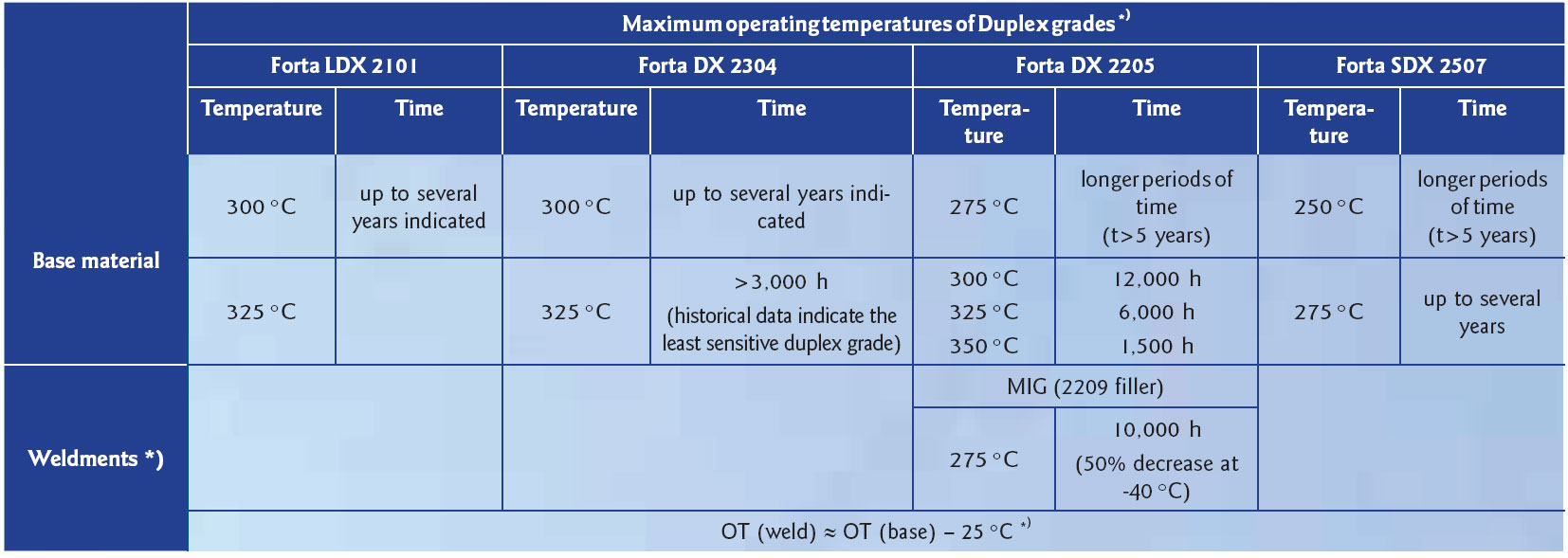

Ukulandela uphando olubanzi lwedatha yovavanyo kunye nemigangatho kube nokwenzeka ukuqulunqa izindululo zamabanga amane aphindwe kabini aphantsi kovavanyo, jonga kwiTheyibhile 3. Kufuneka ithathelwe ingqalelo into yokuba uninzi lwedatha idalwe kwiimfuniselo zaselabhoratri ezenziwe ngamanyathelo obushushu angama-25 °C. .

Kufuneka kwakhona kuqatshelwe ukuba ezi ngcebiso zibhekisa kubuncinci i-50% yobunzima obushiyekileyo kwi-RT.Xa kwitheyibhile "ixesha elide" libonakaliswe ukuba akukho kuncipha okubonakalayo kwi-RT kubhaliweyo.Ngaphezu koko, i-weld ivavanywe kuphela kwi -40 °C.Okokugqibela, kufuneka kuqatshelwe ukuba ixesha elide lokuvezwa lilindelwe kwi-DX 2304, kuthathelwa ingqalelo ukuqina kwayo okuphezulu emva kweeyure ezingama-3,000 zovavanyo.Nangona kunjalo, ukuba sesichengeni kungandiswa kangakanani na kufuneka kuqinisekiswe ngovavanyo olongezelelweyo.

Kukho iingongoma ezintathu ezibalulekileyo ekufuneka uziqaphele:

• Iziphumo zangoku zibonisa ukuba i-welds ikhona, i-OT yehla malunga ne-25 °C.

• Izikhonkwane zexesha elifutshane (amashumi eeyure ku-T=375 °C) zamkelekile kwi-DX 2205. Njengoko i-DX 2304 kunye ne-LDX 2101 zingamabanga asezantsi adibeneyo, ukuthelekisa ubushushu bexesha elifutshane kufuneka kwamkeleke ngokunjalo.

• Xa imathiriyeli ibolile ngenxa yokubola, ukuthomalalisa unyango lobushushu kwi-550 – 600 °C kwi-DX 2205 kunye ne-500 °C ye-SDX 2507 ngeyure e-1 kunceda ukubuyisela ukuqina ngama-70%.

Ixesha lokuposa: Feb-04-2023