Sisebenzisa iikuki ukuphucula amava akho.Ngokuqhubeka nokukhangela le ndawo, uyavumelana nokusebenzisa kwethu iikuki.Iinkcukacha ezongezelelweyo.

Sisebenzisa iikuki ukuphucula amava akho.Ngokuqhubeka nokukhangela le ndawo, uyavumelana nokusebenzisa kwethu iikuki.Iinkcukacha ezongezelelweyo.

Imveliso eyongeziweyo (AM) ibandakanya ukudala izinto ezine-dimensional, enye i-ultra-thin layer ngexesha, iyenza ibize kakhulu kunomatshini wendabuko.Nangona kunjalo, kuphela inxalenye encinci yepowder efakwe ngexesha lenkqubo yendibano ithengiswa kwicandelo.Intsalela ke ayinyibiliki, ngoko inokuphinda isetyenziswe.Ngokwahlukileyo koko, ukuba into yenziwe ngokwesiqhelo, ukususwa kwezinto ngokugaya kunye nomatshini kudla ngokufuneka.

Iimpawu zepowder zinquma iiparitha zomatshini kwaye kufuneka ziqwalaselwe kuqala.Iindleko ze-AM ziya kuba zingenamali zinikwe ukuba i-powder enganyibilikiyo ingcolisekile kwaye ayinakuphinda isetyenziswe.Ukonakaliswa kwepowder kuphumela kwizinto ezimbini: ukuguqulwa kweekhemikhali zemveliso kunye notshintsho kwiimpawu zomatshini ezifana ne-morphology kunye nokusabalalisa ubungakanani be-particle.

Kwimeko yokuqala, umsebenzi oyintloko kukudala izakhiwo eziqinileyo eziqukethe i-alloys ecocekileyo, ngoko kufuneka sigweme ukungcoliswa kwepowder, umzekelo, kunye ne-oxides okanye i-nitrides.Kwimeko yokugqibela, ezi parameters zidibene no-fluidity kunye nokusabalalisa.Ngoko ke, nayiphi na inguqu kwiipropati ze powder ingakhokelela ekuhanjisweni okungafaniyo kwemveliso.

Idatha evela kwiimpapasho zamva nje ibonisa ukuba i-classical flowmeters ayikwazi ukubonelela ngolwazi olwaneleyo malunga nokuhamba kwepowder kwimveliso yezongezo zebhedi.Ngokumalunga nokubonakaliswa kwezinto eziluhlaza (okanye umgubo), kukho iindlela ezininzi ezifanelekileyo zokulinganisa kwimarike ezinokwanelisa le mfuneko.Imeko yoxinzelelo kunye ne-powder flow field kufuneka ibe yinto efanayo kwiseli yokulinganisa kunye nenkqubo.Ubukho bemithwalo yoxinzelelo ayihambelani nokuhamba komphezulu okhululekileyo osetyenziswa kwizixhobo ze-AM kwi-shear cell testers kunye ne-classical rheometers.

I-GranuTools iphuhlise ukuhamba komsebenzi kuphawu lomgubo kwimveliso eyongezelelweyo.Eyona njongo yethu iphambili yayikukuba nesixhobo esinye kwijiyometri yokwenziwa kwenkqubo echanekileyo, kwaye oku kuhamba komsebenzi kwakusetyenziselwa ukuqonda nokulandelela ukuvela komgangatho womgubo ngaphezulu kokupasa koshicilelo oluninzi.Ii-alloys ezininzi ze-aluminium ezisemgangathweni (i-AlSi10Mg) zikhethwe ngamaxesha ahlukeneyo kwimithwalo ye-thermal eyahlukeneyo (ukusuka kwi-100 ukuya kwi-200 ° C).

Ukuthotywa kwe-thermal kunokulawulwa ngokuhlalutya ukukwazi kwepowder ukugcina intlawulo.Iipowders zihlalutyelwe ukuhamba (isixhobo seGranuDrum), ukupakisha i-kinetics (isixhobo seGranuPack) kunye nokuziphatha kwe-electrostatic (isixhobo seGranuCharge).Ukubambisana kunye nokupakisha imilinganiselo ye-kinetics iyafumaneka kwi-powder mass mass.

Iipowders ezisasazeka ngokulula ziya kuba nesalathisi esincinci sokubumbana, ngelixa iipowders ezinokuzaliswa ngokukhawuleza ziza kuvelisa amacandelo omatshini kunye ne-porosity encinci xa kuthelekiswa nemveliso enzima ukuyizalisa.

Iipowders ezintathu ze-aluminium alloy (AlSi10Mg) ezigcinwe kwibhubhoratri yethu iinyanga ezininzi, kunye nokusabalalisa ubungakanani be-particle eyahlukeneyo, kunye ne-316L isampuli yensimbi engenasici, ekubhekiselwe kuyo apha njengeesampuli A, B kunye no-C, zakhethwa.Iimpawu zeesampulu zinokwahluka kwezinye.abavelisi.Isampulu yokuhanjiswa kobungakanani besuntswana kulinganiswe ngohlalutyo lwe-laser diffraction/ISO 13320.

Ekubeni zilawula iiparitha zomatshini, iipropati zepowder kufuneka ziqwalaselwe kuqala, kwaye ukuba sicinga ukuba i-powder enganyibilikiyo ingcolisekile kwaye ingenakuphinda isetyenziswe, iindleko zokwenza okongeziweyo aziyi kuba nezoqoqosho njengoko singathanda.Ke ngoko, iiparamitha ezintathu ziya kuphandwa: ukuhamba komgubo, ukupakisha i-kinetics kunye ne-electrostatics.

Ukusabalalisa kuhambelana nokufana kunye "nobunono" boluhlu lwe powder emva kokusebenza kwakhona.Oku kubaluleke kakhulu njengoko iindawo ezigudileyo kulula ukuprinta kwaye zinokuvavanywa ngesixhobo seGranuDrum esinomlinganiselo wesalathiso sokubambelela.

Ngenxa yokuba ii-pores zibuthathaka kwizinto eziphathekayo, zinokukhokelela ekuqhekekeni.Ukupakisha i-dynamics yiparameter yesibini ebalulekileyo kuba i-powders yokupakisha ngokukhawuleza ine-porosity ephantsi.Oku kuziphatha kuye kwalinganiswa ngeGranuPack enexabiso le-n1/2.

Ubukho bentlawulo yombane kwipowder kudala imikhosi edibeneyo ekhokelela ekubunjweni kwe-agglomerate.I-GranuCharge ilinganisa ukukwazi komgubo ukuvelisa intlawulo ye-electrostatic xa udibana nesixhobo esikhethiweyo ngexesha lokuhamba.

Ngexesha lokucubungula, i-GranuCharge inokuqikelela ukuwohloka kokuhamba, njengokubunjwa kongqimba kwi-AM.Ngaloo ndlela, imilinganiselo efunyenweyo ivakalelwa kakhulu kwimeko yendawo yengqolowa (i-oxidation, ukungcola kunye noburhabaxa).Ukuguga komgubo ofunyenweyo emva koko kunokuchazwa ngokuchanekileyo (± 0.5 nC).

IGranuDrum isekwe kumgaqo wegubu elijikelezayo kwaye yindlela ecwangcisiweyo yokulinganisa ukuhamba komgubo.I-cylinder ethe tyaba eneendonga zecala ezicacileyo iqulethe isiqingatha sesampuli yomgubo.Umgqomo ujikeleza i-axis yayo ngesantya se-angular ye-2 ukuya kwi-60 rpm, kwaye ikhamera yeCCD ithatha imifanekiso (ukusuka kwi-30 ukuya kwi-100 imifanekiso kwi-1 yexesha lesibini).I-interface yomoya / umgubo ichongiwe kumfanekiso ngamnye usebenzisa i-algorithm yokufumanisa edge.

Bala i-avareji indawo yojongano kunye ne-oscillations ejikeleze le ndawo ye-avareji.Kwisantya ngasinye sokujikeleza, i-engile yokuqukuqela (okanye “i-angle eguquguqukayo yokuphumla”) αf ibalwa ukusuka kwindawo yojongano oluphakathi, kunye nesalathiso sokuncamathela esiguquguqukayo σf, esibhekiselele kwikhonkco phakathi kwamasuntswana, sihlalutywa ukusuka kujongano oluguquguqukayo.

I-angle yokuhamba ithonywa inani leeparamitha: ukungqubuzana phakathi kwamasuntswana, imilo kunye nokubambisana (van der Waals, i-electrostatic kunye ne-capillary forces).Iipowder ezidibeneyo ziphumela ekuhambeni kwexesha, ngelixa i-powders engahambelaniyo ibangela ukuhamba rhoqo.Amaxabiso amancinci eengile yokuqukuqela αf ahambelana neempawu zokuhamba kakuhle.Isalathiso sokubambelela esiguquguqukayo esisondele kwi-zero sihambelana nepowder engahambelaniyo, ngoko ke, njengoko ukudibanisa kwepowder kwanda, isalathisi sokubambelela sanda ngokufanelekileyo.

I-GranuDrum ikuvumela ukuba ulinganise i-angle ye-avalanche yokuqala kunye ne-aeration ye powder ngexesha lokuhamba, kunye nokulinganisa isalathisi sokubambelela σf kunye ne-angle yokuhamba αf ngokuxhomekeke kwisantya sokujikeleza.

I-GranuPack yobuninzi be-bulk, i-tapping density kunye ne-Hausner ratio measurements (ekwabizwa ngokuba "yi-touch tests") zithandwa kakhulu kwi-powder characterization ngenxa yokulula kunye nesantya sokulinganisa.Ubuninzi bepowder kunye nokukwazi ukwandisa ukuxinana kwayo yimilinganiselo ebalulekileyo ngexesha lokugcina, ukuthutha, i-agglomeration, njl. Inkqubo ecetyiswayo ichazwe kwi-Pharmacopoeia.

Olu vavanyo olulula luneengxaki ezintathu ezinkulu.Imilinganiselo ixhomekeke kumqhubi kwaye indlela yokuzalisa ichaphazela umthamo wokuqala we powder.Ukulinganisa okubonakalayo komthamo kunokukhokelela kwiimpazamo ezinzulu kwiziphumo.Ngenxa yokulula kolingelo, siye satyeshela amandla okudibanisa phakathi kwemilinganiselo yokuqala neyokugqibela.

Ukuziphatha komgubo ofakwe kwi-outlet eqhubekayo yahlalutywa kusetyenziswa izixhobo ezizenzekelayo.Ukulinganisa ngokuchanekileyo i-Coefficient ye-Hausner Hr, ingxinano yokuqala ρ(0) kunye noxinano lokugqibela ρ(n) emva konqakrazo lwe-n.

Inani leempompo lidla ngokulungiswa ku-n=500.IGranuPack sisilinganisi esizenzekelayo nesiqhubela phambili sokucofa ingxinano esekwe kuphando oluguquguqukayo lwamva nje.

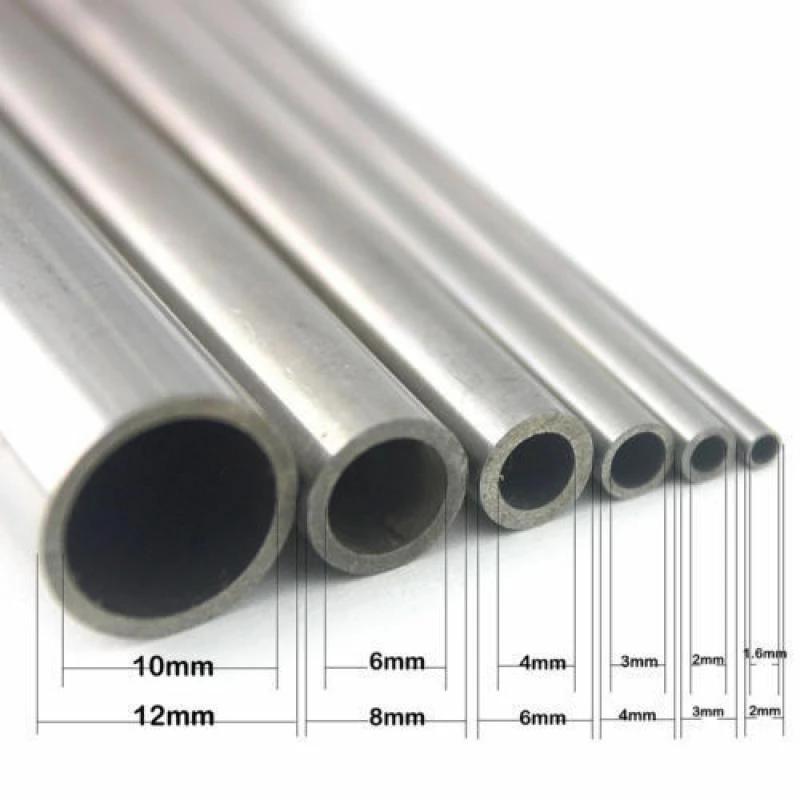

Ezinye izalathisi zinokusetyenziswa, kodwa azidweliswanga apha.Umgubo ufakwa kwiityhubhu zetsimbi kwaye uhamba ngenkqubo engqongqo yokuqalisa ngokuzenzekelayo.I-extrapolation yeparamitha eguqukayo n1/2 kunye nobuninzi bobuninzi ρ(∞) ithathwa kwigophe lokuxinana.

Isilinda esingenanto esikhaphukhaphu sihlala phezu kwebhedi yomgubo ukugcina inqanaba lepowder/air interface ngexesha lokuxinana.I-tube equkethe isampuli ye powder iphakama ukuya kubude obusisigxina ∆Z kwaye emva koko iwela ngokukhululekile ukuphakama, ngokuqhelekileyo igxininiswe ku-∆Z = 1 mm okanye ∆Z = 3 mm, ilinganiswe ngokuzenzekelayo emva kwempembelelo nganye.Ngokuphakama, unako ukubala umthamo we-V wemfumba.

Uxinaniso lumlinganiselo wobunzima m ukuya kumthamo we-V we-powder layer.Ubunzima bomgubo m buyaziwa, ubuninzi ρ busetyenziswa emva kokukhululwa ngalunye.

I-Coefficient ye-Hausner Hr inxulumene nezinga lokudibanisa kwaye ihlalutywa yi-equation Hr = ρ(500) / ρ(0), apho ρ(0) iyixinaniso yesambuku yokuqala kunye ρ(500) yimpompo ebalwa emva kwe-500 iimpompo.Iziphumo ziphinda ziphindwe kunye nenani elincinci le powder (ngokuqhelekileyo i-35 ml) usebenzisa indlela yeGranuPack.

Iimpawu zepowder kunye nobunjani bezinto ezivela kuyo isixhobo ziyiparameters eziphambili.Ngexesha lokuhamba, iintlawulo ze-electrostatic ziveliswa ngaphakathi komgubo, kwaye ezi ntlawulo zibangelwa yi-triboelectric effect, utshintshiselwano lweentlawulo xa izinto ezimbini eziqinileyo zidibana.

Xa umgubo uhamba ngaphakathi kwesixhobo, iziphumo ze-triboelectric zenzeka kuqhagamshelwano phakathi kwamasuntswana kunye noqhagamshelwano phakathi kweqhekeza kunye nesixhobo.

Xa udibana nezinto ezikhethiweyo, iGranuCharge ilinganisa ngokuzenzekelayo inani lentlawulo ye-electrostatic eyenziwa ngaphakathi kwipowder ngexesha lokuhamba.Isampuli yepowder igeleza kwi-vibrating V-tube kwaye iwela kwikomityi yeFaraday exhunywe kwi-electrometer elinganisa umrhumo ofunyanwa ngumgubo njengoko uhamba nge-V-tube.Ukufumana iziphumo eziphinda ziphindaphindeke, yondla i-V-tube rhoqo ngesixhobo esijikelezayo okanye esingcangcazelayo.

Isiphumo se-triboelectric sibangela ukuba into enye ifumane ii-electron kumphezulu wayo kwaye ngaloo ndlela ihlawuliswe kakubi, ngelixa enye into ilahlekelwa yi-electron kwaye ihlawuliswe ngokufanelekileyo.Ezinye izinto zifumana ii-electron ngokulula kunezinye, kwaye ngokufanayo, ezinye izinto zilahlekelwa zii-electron ngokulula.

Yeyiphi imathiriyeli eba yimbi kwaye ibe yeyiphi na ixhomekeke kutyekelo olunxulumene nezinto ezibandakanyekayo ekufumaneni okanye ekulahlekeni kwee-electron.Ukumela le mikhwa, uchungechunge lwe-triboelectric oluboniswe kwiThebhile 1 lwaphuhliswa.Iimathiriyeli ezithanda ukuhlawuliswa ngokufanelekileyo kunye nezinye ezithanda ukuhlawuliswa kakubi zidweliswe, ngelixa izixhobo ezingabonisi ukuthambekela kokuziphatha zidweliswe embindini wetheyibhile.

Kwelinye icala, le theyibhile ibonelela kuphela ngolwazi malunga nendlela yokuziphatha kwentlawulo yezinto eziphathekayo, ngoko ke iGranuCharge yenzelwe ukubonelela ngexabiso elichanekileyo lokuziphatha kwentlawulo ye powder.

Izilingo ezininzi zenziwa ukuhlalutya ukubola kwe-thermal.Iisampuli zishiywe kwi-200 ° C kwiyure enye ukuya kwiiyure ezimbini.Umgubo uhlalutywa ngokukhawuleza ngeGranuDrum (igama le-thermal).Umgubo ke ufakwa kwisikhongozeli ude ufikelele kwiqondo lobushushu be-ambient uze emva koko uhlalutywe kusetyenziswa iGranuDrum, iGranuPack kunye neGranuCharge (oko kukuthi “kubanda”).

Iisampulu ezikrwada zahlalutywa kusetyenziswa iGranuPack, iGranuDrum kunye neGranuCharge kubushushu obufanayo/ubushushu begumbi, okt ukufuma okunxulumene ne-35.0 ± 1.5% kunye nobushushu obuyi-21.0 ± 1.0 °C.

Isalathiso sokubambisana sibala ukuhamba kwepowder kwaye ihambelana notshintsho kwindawo yokudibanisa (umgubo / umoya), obonisa kuphela amandla amathathu oqhagamshelwano (van der Waals, capillary kunye ne-electrostatic).Phambi kovavanyo, bhala phantsi ukufuma okunxulumeneyo (RH, %) kunye nobushushu (°C).Emva koko uthele umgubo kwisitya somgqomo kwaye uqale uvavanyo.

Sigqibe kwelokuba ezi mveliso azikhathaleli kwi-caking xa kuqwalaselwa iiparamitha zethixotropic.Okubangela umdla kukuba, uxinzelelo lwe-thermal lutshintshe indlela yokuziphatha ye-rheological powders yeesampulu A kunye no-B ukusuka ekutshibeni kwe-chear ukuya ku-chear thinning.Kwelinye icala, iiSampuli C kunye ne-SS 316L azichatshazelwanga bubushushu kwaye zibonise ukucheba kuphela.Umgubo ngamnye ubonise ukusasazeka okungcono (oko kukuthi isalathiso sokubambisana esisezantsi) emva kokufudumeza kunye nokupholisa.

Isiphumo sobushushu sikwaxhomekeke kwindawo ethile yomphezulu wamasuntswana.Okukhona i-thermal conductivity yezinto eziphathekayo, impembelelo enkulu kwiqondo lokushisa (okt ???225 °?=250?.?-1.?-1) kunye ne-?316?225°?=19?.?-1.?-1), okukhona amasuntswana amancinane, kokukhona kubaluleke kakhulu umphumo wobushushu.Ukusebenza kumaqondo obushushu aphakamileyo lukhetho olulungileyo lwe-aluminium alloy powders ngenxa yokwanda kokusasazeka, kwaye iisampuli ezipholileyo zifezekisa ukugeleza okungcono ngakumbi xa kuthelekiswa nomgubo ococekileyo.

Ngovavanyo ngalunye lweGranuPack, ubunzima bepowder burekhodwe ngaphambi kovavanyo ngalunye, kwaye isampuli yayiphantsi kweempembelelo ze-500 kunye ne-frequency frequency ye-1 Hz kunye nokuwa kwamahhala kweseli yokulinganisa ye-1 mm (impembelelo yamandla ∝).Iisampulu zikhutshwa kwiiseli zokulinganisa ngokwemiyalelo yesoftware ezimeleyo kumsebenzisi.Imilinganiselo yaphinda iphindwe kabini ukuvavanya ukuveliswa kwakhona kunye nokuhlola intsingiselo kunye nokuphambuka okusemgangathweni.

Emva kokuba uhlalutyo lweGranuPack lugqityiwe, ukuxinana kokuqala kokupakisha (ρ(0)), ukuxinana kokugqibela kokupakisha (ngocofa izihlandlo ezininzi, n = 500, oko kukuthi ρ(500)), umlinganiselo weHausner/Carr index (Hr/Cr) , kunye nezimbini ezirekhodiweyo. iparameters (n1/2 kunye ne τ) ezinxulumene noguquguquko.Olona uxinano ρ(∞) lukwabonisiwe (jonga iSihlomelo 1).Itheyibhile engezantsi icwangcisa kwakhona idatha yovavanyo.

Amanani 6 kunye ne-7 abonisa i-curves yokudibanisa ngokubanzi (i-bulk density ngokumelene nenani leempembelelo) kunye ne-n1 / 2 / Hausner parameter ratio.Iibhari zempazamo ezibalwe kusetyenziswa i-avareji zibonisiwe kwigophe ngalinye, kwaye unxaxhesho olusemgangathweni lubalwe kuvavanyo lokuphinda-phinda.

Imveliso ye-316L yensimbi engenasici yayiyeyona mveliso inzima (ρ(0) = 4.554 g/mL).Ngokumalunga nokuxinana kweetephu, i-SS 316L isengoyena mgubo unzima (ρ(n) = 5.044 g/mL), ilandelwa yiSample A (ρ(n) = 1.668 g/mL), ilandelwa yiSample B (ρ (n) = 1.668 g/ml) (n) = 1.645 g/ml).Isampulu C yayiyeyona iphantsi (ρ(n) = 1.581 g/mL).Ngokutsho kobuninzi bobuninzi bomgubo wokuqala, sibona ukuba isampuli A yeyona nto ilula, kwaye ithathela ingqalelo impazamo (1.380 g / ml), iisampuli B kunye neC zinexabiso elilinganayo.

Xa i-powder ishushu, i-Hausner ratio yayo iyancipha, eyenzeka kuphela kwiisampuli B, C kunye ne-SS 316L.KwiSampuli A, oku akunakukwenziwa ngenxa yobukhulu beebar zempazamo.Kwi-n1/2, iintsingiselo zeparameter zinzima kakhulu ukuchonga.Isampula A kunye ne-SS 316L, ixabiso le-n1 / 2 lehla emva kwe-2 h kwi-200 ° C, ngelixa i-powders B kunye ne-C yanda emva kokulayishwa kwe-thermal.

I-feeder vibrating isetyenziswe kumfuniselo ngamnye weGranuCharge (jonga uMfanekiso 8).Sebenzisa i-316L ipayipi yensimbi engenasici.Imilinganiselo yaphindwa ngamaxesha e-3 ukuvavanya ukuveliswa kwakhona.Ubunzima bemveliso esetyenzisiweyo kumlinganiselo ngamnye babumalunga nama-40 ml kwaye akukho mgubo ufunyenwe emva komlinganiselo.

Ngaphambi kovavanyo, ubunzima bomgubo (mp, g), ukufuma komoya ohambelanayo (RH, %), kunye nobushushu (°C) zirekhodwa.Ekuqaleni kovavanyo, linganisa ubuninzi bentlawulo yomgubo wokuqala (q0 ngeµC/kg) ngokungenisa umgubo kwikomityi yeFaraday.Ekugqibeleni, bhala ubunzima bomgubo kwaye ubale ubuninzi bentlawulo yokugqibela (qf, µC / kg) kunye ne-Δq (Δq = qf - q0) ekupheleni kovavanyo.

Idatha ye-GranuCharge eluhlaza iboniswe kwiThebhile 2 kunye ne-Figure 9 (σ yi-standard deviation ebalwe kwiziphumo zovavanyo lokuphindaphinda), kwaye iziphumo zinikezelwa njenge-histograms (kuphela i-q0 kunye ne-Δq ibonisiwe).I-SS 316L yayinexabiso eliphantsi lokuqala;oku kunokuba ngenxa yokuba le mveliso ineyona PSD iphezulu.Ngokumalunga nexabiso lokuqala lentlawulo ye-aluminium engundoqo ye-powder, akukho zigqibo ezinokuthi zenziwe ngenxa yobukhulu beempazamo.

Emva kokuqhagamshelana ne-316L ipayipi yensimbi engenasici, isampuli A ifumene inani elincinci lentlawulo xa lithelekiswa ne-powders B kunye ne-C, ebonisa indlela efanayo, xa i-SS 316L powder ixutywa nge-SS 316L, ukuxinwa kwentlawulo kufutshane ne-0 kufunyenwe (jonga i-triboelectric series).Imveliso ye-B isahlawuliswa ngaphezu kwe-A. Kwisampula C, umgangatho uyaqhubeka (intlawulo yokuqala efanelekileyo kunye nentlawulo yokugqibela emva kokuvuza), kodwa inani leentlawulo landa emva kokuthotywa kwe-thermal.

Emva kweeyure ze-2 zoxinzelelo lwe-thermal kwi-200 ° C, ukuziphatha komgubo kuba yinto emangalisayo.Kwiisampulu A kunye no-B, intlawulo yokuqala iyehla kwaye intlawulo yokugqibela iyatshintsha ukusuka ku-negative ukuya kwi-positive.I-SS 316L powder yayineyona ntlawulo yokuqala ephezulu kunye nokutshintshwa kwentlawulo yayo yaba yinto enhle kodwa yahlala iphantsi (okt 0.033 nC / g).

Siphande umphumo wokuthotywa kwe-thermal kwindlela yokuziphatha edibeneyo ye-aluminium alloy (AlSi10Mg) kunye ne-316L ye-powders yensimbi engenasici ngelixa sihlalutya i-powders yasekuqaleni kwi-air ambient emva kweeyure ze-2 kwi-200 ° C.

Ukusetyenziswa kweepowder kwiqondo lokushisa eliphezulu kunokuphucula ukusasazeka kwemveliso, kwaye esi siphumo sibonakala sibaluleke kakhulu kwiipowder ezinomgangatho ophezulu ophezulu kunye nezixhobo ezine-conductivity ephezulu ye-thermal.I-GranuDrum yayisetyenziselwa ukuvavanya ukuhamba, i-GranuPack yayisetyenziselwa uhlalutyo lokuzaliswa okuguquguqukayo, kwaye i-GranuCharge yayisetyenziselwa ukuhlalutya i-triboelectricity ye powder edibene ne-316L yensimbi engenasici.

Ezi ziphumo zisekwe kusetyenziswa iGranuPack, ebonisa ukuphuculwa kwe-Hausner coefficient ye powder nganye (ngaphandle kwesampuli A ngenxa yephutha lobungakanani) emva kwenkqubo yoxinzelelo lwe-thermal.Ukujonga iiparamitha zokupakisha (n1/2), bekungekho ntsingiselo icacileyo njengoko ezinye iimveliso zibonise ukonyuka kwesantya sokupakisha ngelixa ezinye zineempembelelo ezichaseneyo (umz. Iisampulu B kunye no-C).

Ixesha lokuposa: Jan-10-2023